Improving Manufacturing Quality with H2O.ai and Snowflake

Manufacturers are rapidly expanding their machine learning use cases by leveraging the deep integration between Snowflake’s Data Cloud and the H2O AI Cloud.

Many current manufacturing quality checks require that sensor data and image data be processed and analyzed separately. Standard tooling presents challenges in storing and referencing these data types together. Often, comparison on sensor metrics can be automated as the data is represented as numeric values. But images often required a separate, and sometimes manual, process for analysis.

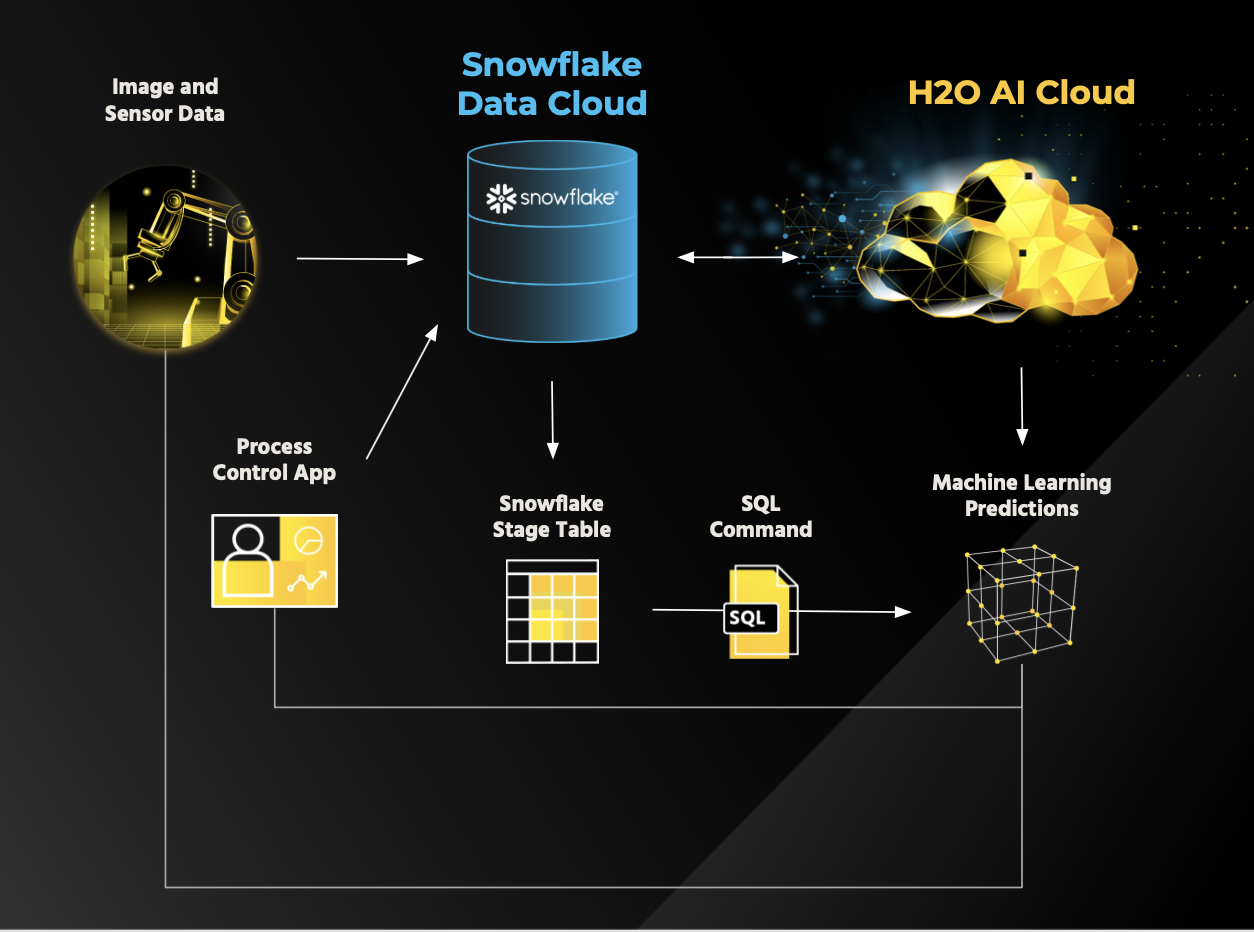

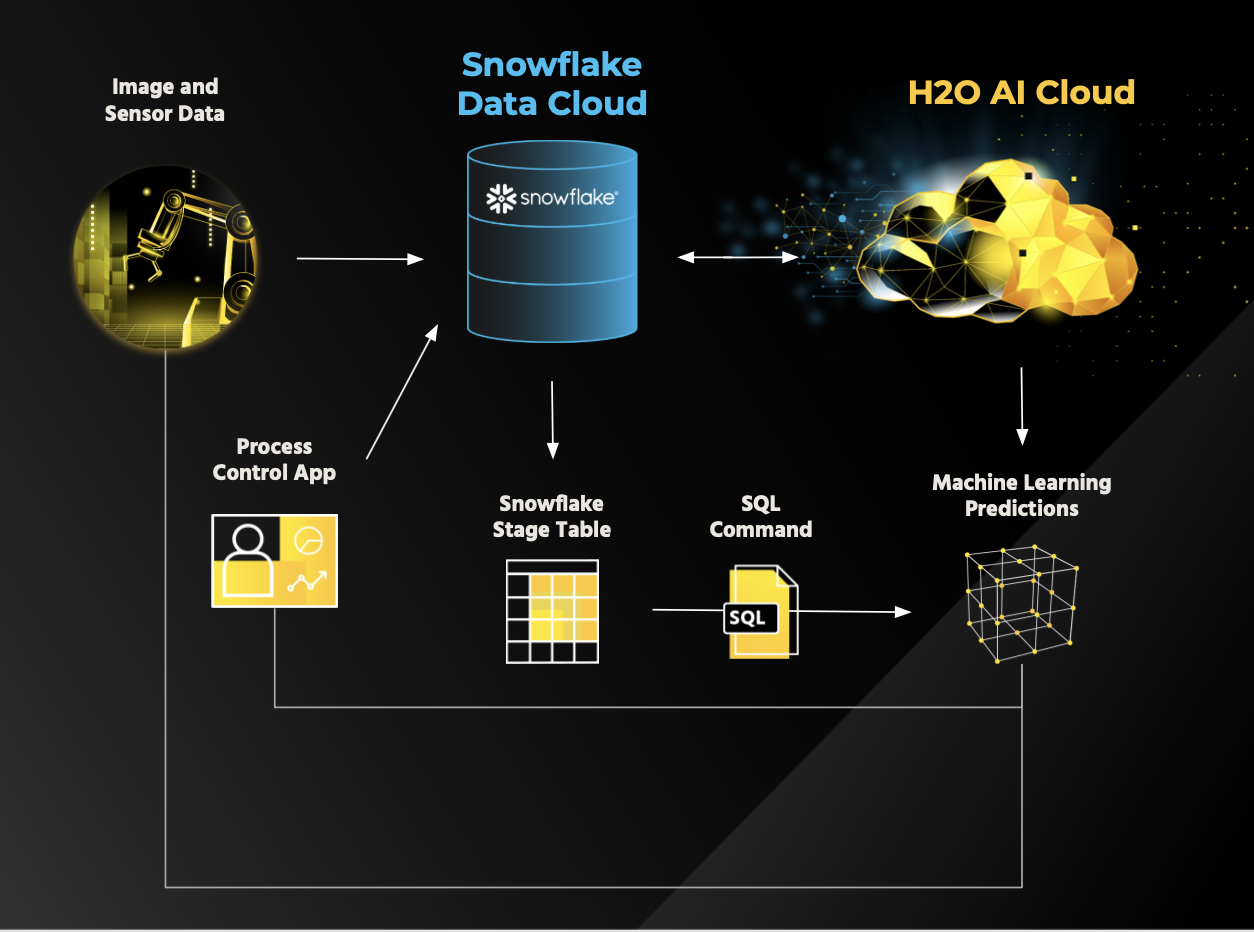

With new integration capabilities between Snowflake and H2O.ai, sensor data and images stored in the Snowflake Data Cloud can now be used by H2O.ai models directly in a SQL statement. This enables fast, consistent validation of the manufacturing components being analyzed in near real time. Additionally, since H2O machine learning predictions are available using standard SQL, any application or downstream manufacturing tooling can also access model predictions.

Combining both sensor and image data has been shown to improve overall product quality, leading to reduced manufacturing costs, increased operational efficiencies and a better customer experience.

Quality Improvements with Machine Learning

Getting a prediction on an image is as simple as writing a SQL statement, as H2O models can be used as SQL functions. And because H2O models are available via a SQL function, any application that uses Snowflake as the system of record can leverage this new powerful combination.

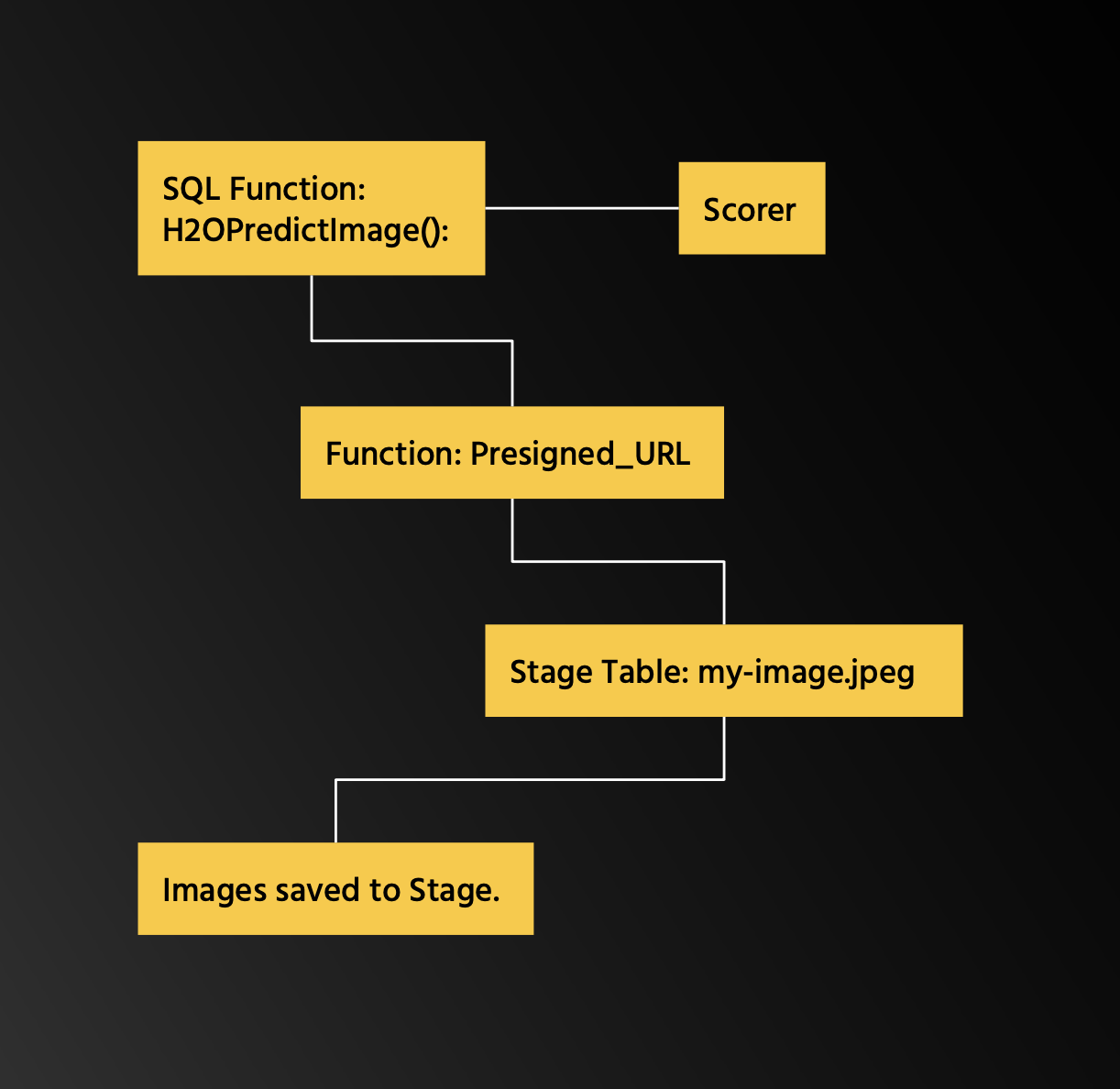

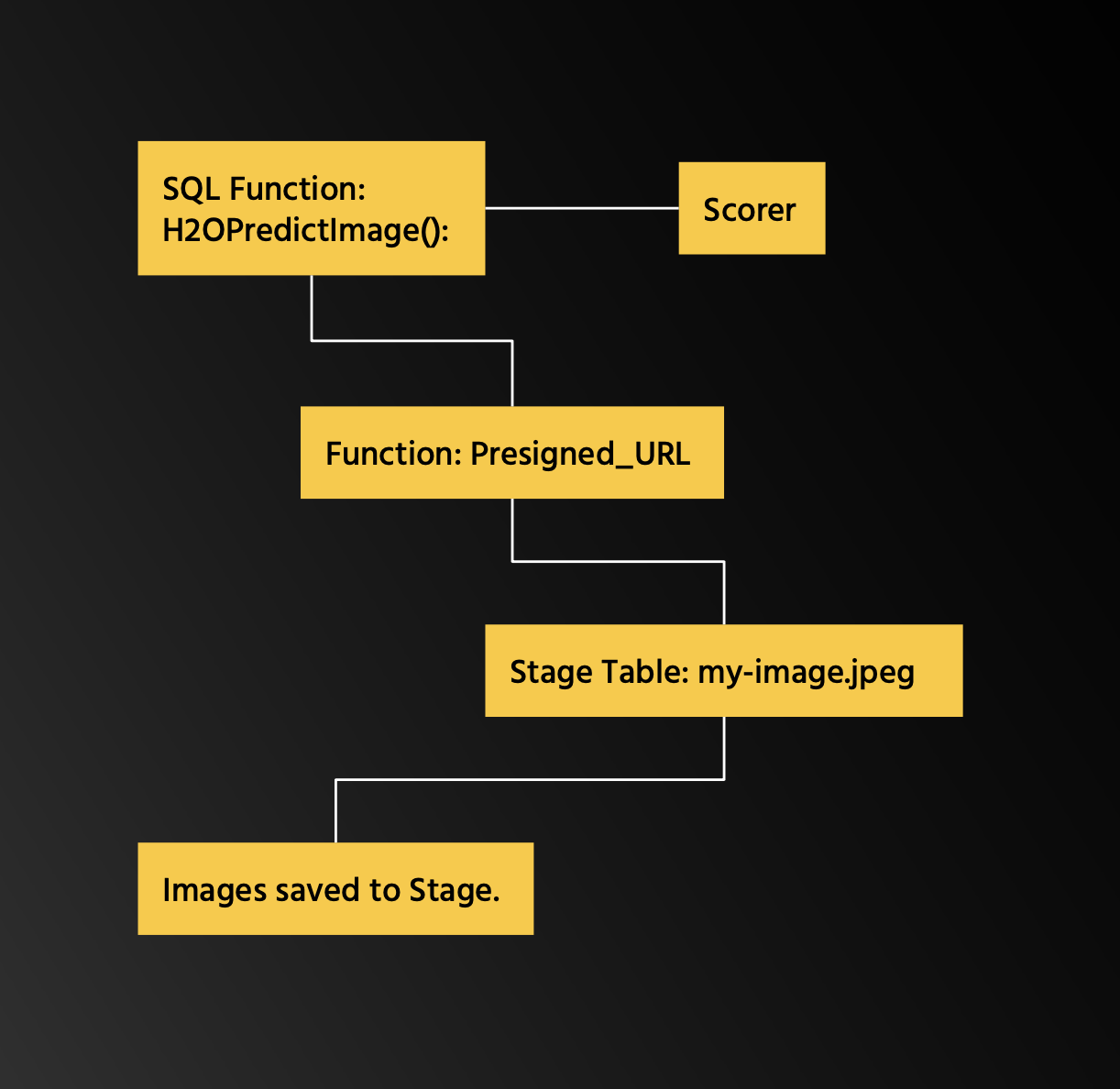

Including images along with traditional numerical and string data significantly elevates real-time inferencing. The above SQL uses an image stored in the Snowflake Stage table and passes a presigned URL to the scoring function so the image can be accessed by the scorer. The image is then processed and scored, with the resulting prediction returned to Snowflake. This diagram shows how simple it is to put these new capabilities to use.

Images are initially captured as components leave the assembly line and stored in a Snowflake Stage table. Using the H2O model, a SQL command then runs predictions on the images and other sensor data. These predictions are available to flow directly back to the assembly line or be consumed by process control applications that reflect analysis of the manufacturing process.

This application is not limited to manufacturing. Adding images to your machine learning scoring have benefits across all industries from healthcare to insurance and construction.

Find out more about Snowflake and H2O.ai’s partnership at h2o.ai/snowflake.